Who and what is Texible?

Thomas: We are a spin-off of the University of Innsbruck, Tirol, to further introduce research results into the smart textile market.

Our challenge is that textile companies, in the classic sense, mostly put their focus on fashion. However, technical textiles need to be marketed in a completely different way and often bring a higher degree of consultancy. Therefore we aim to exploit research results and ideas for prototypes to develop final products. Our own product Wisbi® , a bed pad for people in care, detects wetness and is a direct result of our research. Additionally, we do a lot of contracted research as we intend to share our know-how and network with other companies & clients.

How important is the cooperation with other clients?

Thomas: Particularly with contracted research, a close fine-tuning with the client is instrumental to us. Many clients know more about textiles rather than technical product development. Generally speaking, feedback from the end customer is always essential, i.e., about prototypes to perfectly adapt them to the end customer´s needs. It’s fairly straightforward to develop a product along with certain specifications. However, the suitability for daily use is the challenging part, i.e., the appropriate handling of new technologies by the end customer.

What’s the biggest challenge in your work?

Thomas: Every client’s project is different, and we always start at zero with every research and development because there is no smart textile standard yet in our field, and each company has a different approach. Further, one solution may be suitable for one product but not for another. Hence, each new product is a challenge. This is the charm of our industry; it’s very diverse.

What do you appreciate most about our work? Where’s the biggest fun?

Thomas: The smart textiles industry is very interdisciplinary – you have to know various disciplines, i.e., electrical engineering, textiles, electronics, IT, plastics engineering, process engineering, etc., to develop a functional smart textile product. It’s many-layered, and you learn a lot with every product development.

How will the smart textile industry evolve in the coming years?

Thomas: We are convinced that this is a promising market. However, time is a critical factor – the complexity of smart textiles gets mostly underrated. Big textile companies cannot easily integrate smart textiles R&D in their existing structures and hence approach start-ups.

Smart textiles will influence all life aspects because fabrics are already found everywhere, i.e., rugs, home textiles, clothing, or protective work clothing. Integration of functionality is hence only a logical and sensible move. Seen from today’s technical status-quo, smart textiles become affordable and thus better marketable. But one, of course, needs the end customer to embrace the product. We are convinced that usability, functionality, price, and look are decisive for adding value to the end customer.

What was your first impression of ADRESYS?

Thomas: Surprise! Finally, a technology company that knows how product development works. Many textile companies still approach research with a pre-defined budget. With this budget, even field research, etc., should be covered, which is mostly unrealistic. ADRESYS knows the meaning of a product life-cycle, how a pre-launch works, and we didn’t need any „educational work“. Hence, Texible is the logical addition – ADRESYS adds technical know-how, Texible contributes textile know-how and the necessary textile network. This is the attraction and charm of an R&D partnership. That’s how Texible generates added value to ADRESYS.

What do you do for us?

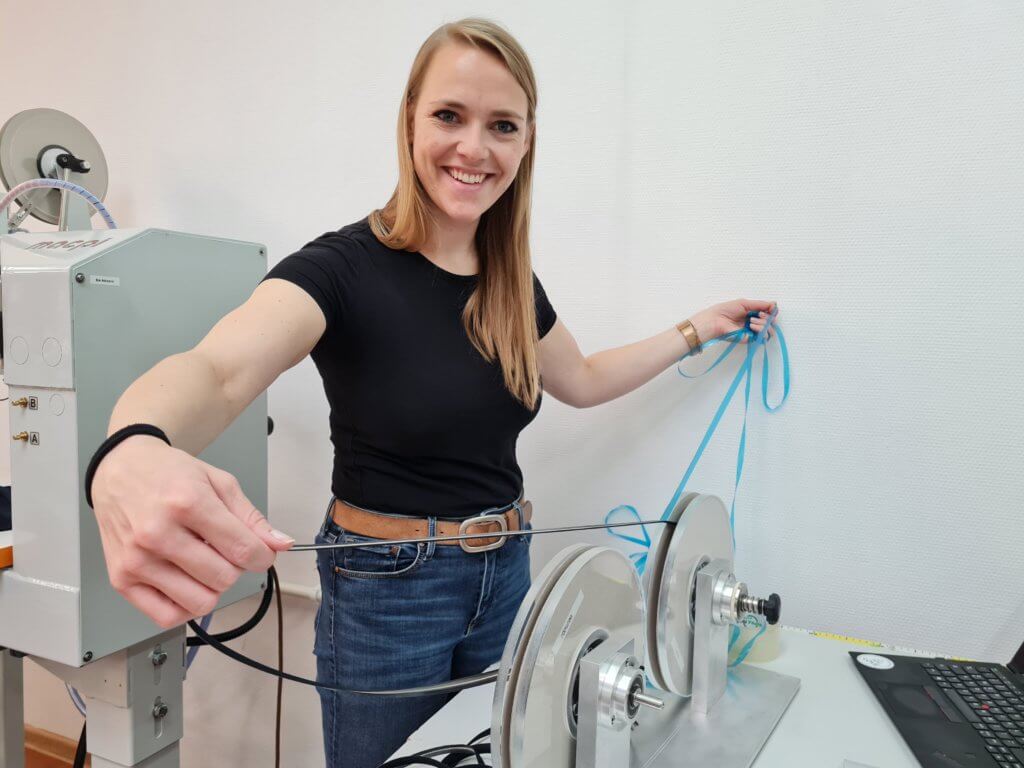

Thomas: It´s a fairly wide range, pretty much everything one can offer in the textile field. Checking options is the essence of every development project. We have co-developed many processes, for instance, a conductive synthetic, how contacting can be made conductive and which electrodes work best. It has always been important to us that our processes also work for mass production.

What would you do if you didn’t work for Texible?

Thomas: I always loved interdisciplinary work. In other words, I would probably do something similar. I would probably still be in project management and pick complex projects that are attractive, demanding, and always bring along something new.

Last words?

Thomas: I wish you and us a lot of success!

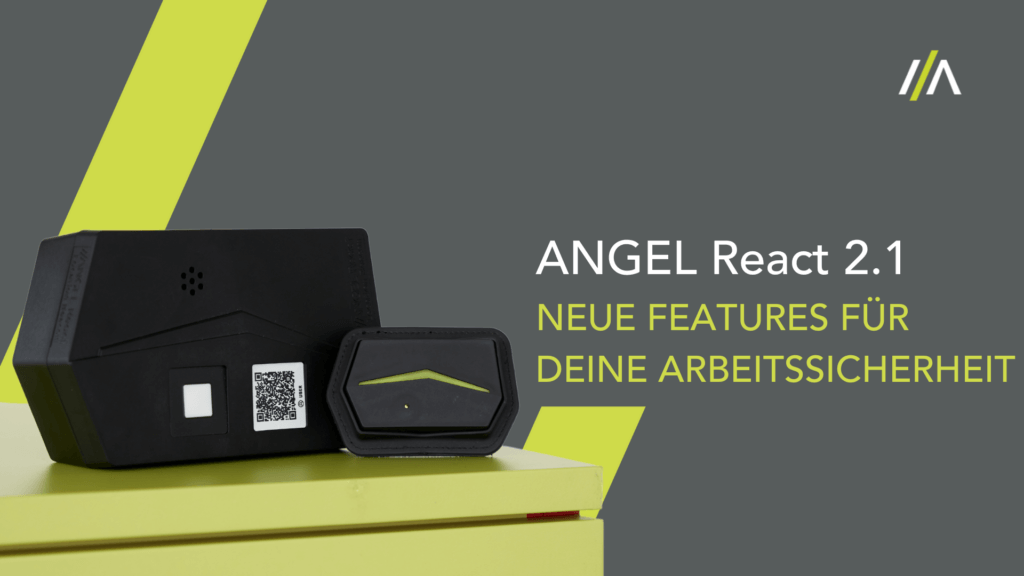

ANGEL React & ADRESYS

ANGEL React & ADRESYS  ANGEL React & ADRESYS

ANGEL React & ADRESYS  ANGEL React & ADRESYS

ANGEL React & ADRESYS